Dried kakis, which are traditional sweets made of one of the few fruits native to Japan, now face a crisis due to a surge of sugar imports, changes in the Japanese people's dietary habits, and the advancing age of their producers.

How Dried Kakis Are Made

The dojo Hachiya kaki, which was presented to successive shoguns, is probably the most highly priced brand among dried-kaki products. The best fruits with good color and shape, which account for some 30% of the crop, cost ¥1,000 (about $10) per piece. A case of 400 grams or more can cost 3,000 yen and is suitable as a gift, as the fruits are packed in neat wooden boxes. When seeing the hard work on site to create the finest dried fruits, people will no longer think the prices are too expensive.

To create quality dried kakis, producers must first grow big fruits with fine texture and taste; otherwise, all the ensuing hard work will be in vain. Koichi Horibe, chairman of the dojo Hachiya kaki association, has about 100 kaki trees in his field. At most they stand only as tall as the average human. "They are delicate trees, and become prone to diseases when they grow too tall," explains Horibe. So, when he grafts kaki trees, he uses the mountain kaki species as the base root. Although the fruits are small, his mountain kaki trees are close to the original species and resilient to both diseases and cold.

A field of Hachiya-kaki trees "demands meticulous care throughout the year." In the winter after the harvest, farmers add fertilizer to the soil so that the trees will bear good fruits next year too. From January to March, growers scrub off the surface of the trees to keep away insects and diseases. In mid-May, they also remove redundant blossoms, and in June they remove surplus new buds to avoid the scrambling of branches. In July, growers remove all but one fruit on each branch. When the harvest approaches, growers add fertilizer to prepare the field for the coming winter. Straws are spread at the foot of each tree to protect the intrusion of bacteria, and fallen leaves are neatly removed so as not to give any room for germs. The care taken to grow kakis in Hachiya is reminiscent of how the finest vineyards are tended.

The following outlines the process for making dried kakis.

Harvesting: In the middle of November, later than for most other kaki species; the fruits are left to mature for three to seven days, until their texture becomes as soft as earlobes.

Peeling: A process done by hand, with the use of peelers, unlike Ichiya kakis; within three hours after the peeling, the fruits are fumed with sulfur for about 20 minutes to ease astringency. A chain of fruits, with two kakis bound together horizontally, is hung in a breezy shade for 10 to 15 days.

Sun-drying: Only from 9 in the morning until 4 in the afternoon on the drying platform, for 10 to 25 days; the fruits are turned around many times so that both sides are exposed to wind. On rainy days they are placed in front of fans. At the same time, the stems of the fruits are trimmed in a neat uniform manner.

Kneading: 20 to 25 days after peeling, they are kneaded during the sunny hours when the fruits "shine." They will turn black if kneaded in humid air, which makes their surface sticky.

Sweeping the surface with rice spikes: The surface is gently scratched, leaving tiny scars on the skin, which prompts the sugar from inside the fruit to cover the surface. The sugar then frosts over the skin.

Shipment: After several more days of sun drying, the fruits are ready for shipment in the middle of December. The Murases buy rice straw from their relatives and use them to lay the gift boxes. They beat the straw, removing hardened and discolored areas, in a process that reduces the straw to 40% of the original volume. The straws are cut to the same length and placed in the boxes. "If we could use fresh green stems, that would make our kakis look even more vivid," says Kotoko, daughter of Toshio Murase. The entire process is done by members of the Murase family. They cut bamboo trees growing in the hills behind their house and use them to hang their fruits. The family does not use modern conveniences, such as plastic. This reflects the esthetic underlying the kaki-growing tradition.

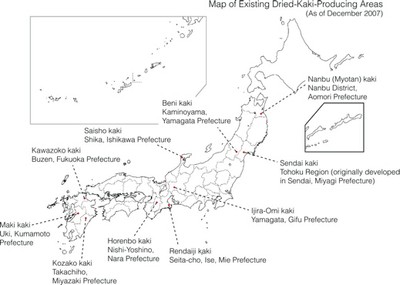

Where Are They Produced?

The town of Hachiya is in Gifu Prefecture, central Japan, and is about an hour's drive from Nagoya. It is part of the Mino Plain and is blessed with warm sunshine through much of the year, with little snow in winter. This contrasts with the image of harsh winters people have of Gifu's more mountainous areas. The genial weathers make Hachiya an rich farming area, known for its production of sweet fuyugaki and pears.

The Hachiya kaki is a bitter, large-sized kaki that turns sweet only when dried and grows only in this town. When Shogun Tokugawa Iyeyasu passed by the village on a military campaign en route to nearby Ogaki Castle, local farmers presented him with these persimmons. The shogun is said to have been much delighted with the gift, as "large kaki" in Japanese is pronounced ogaki , which was the name of the castle he was about to attack. This anecdote reflects Hachiya's long history as a center for large kaki production. The Hachiya species has since spread to Fukushima, Nagano, and 13 other prefectures.

Besides its size, characteristics of the Hachiya kaki include the fine texture of its fruit and a low degree of moistness, an ideal combination in making dried kakis. A historical area on the opposite side of Mino-Kamo Station does not produce any Hachiya kakis, though; the area dotted with old lodges is apparently too humid due to the influence of the nearby Kiso River.

Despite being surrounded by such snow-heavy areas as Sekigahara, Ena, and Hida, Hachiya gets little snow. Instead, winters are mostly sunny, ideal for making dried kakis, as the process is to a considerable extent dependent on weather conditions. Differences in daytime and nighttime temperatures, little rainfall, and adequate sunshine all intensify the delicate tastes of the fruit.

Encroaching Urbanization

While many families still grow a Hachiya kaki tree, most of the 80 growers of the fruit are concentrated in a narrow area clustered around Hachiya.

This community with a thousand-year tradition is losing much of its historical landscape, however, due to the construction of modern homes, partly owing to its proximity to Nagoya, one of Japan's largest cities.

The kaki is one of the few fruits that are native to Japan. In 1912 there were almost a thousand local kaki species in Japan, according to Professor Satoshi Taira of Yamagata University, citing a government survey from that period. Now, fewer than a third of them remain. Taira blames this change on the urbanization of rural communities and Westernization of dietary habits. There is a danger, therefore, that Hachiya, which is easily accessible not only from Nagoya but also from Tokyo, could become swept up in such changes.

Photo: Yasuko Fujisawa